The automotive industry is undergoing rapid transformation, with automation playing a crucial role in driving efficiency, productivity, and cost-effectiveness. At the center of this evolution are Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs). These technologies are reshaping material handling, logistics, and assembly processes, and integrating into smart manufacturing systems as well as other industries

At SK Robotics, we engineer AMRs that are built to meet the demands of modern automotive production. Here's how AGVs and AMRs are revolutionizing the industry.

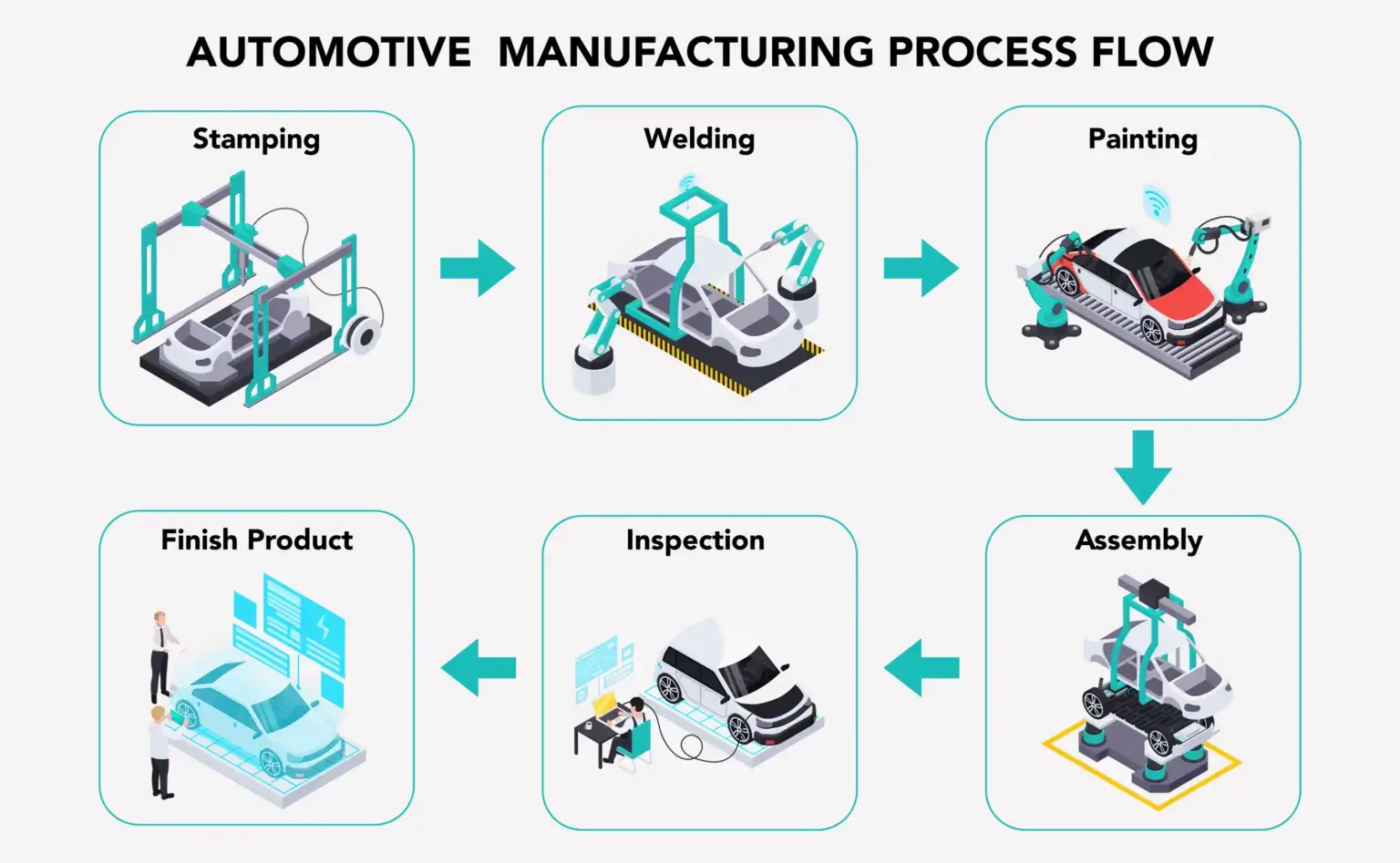

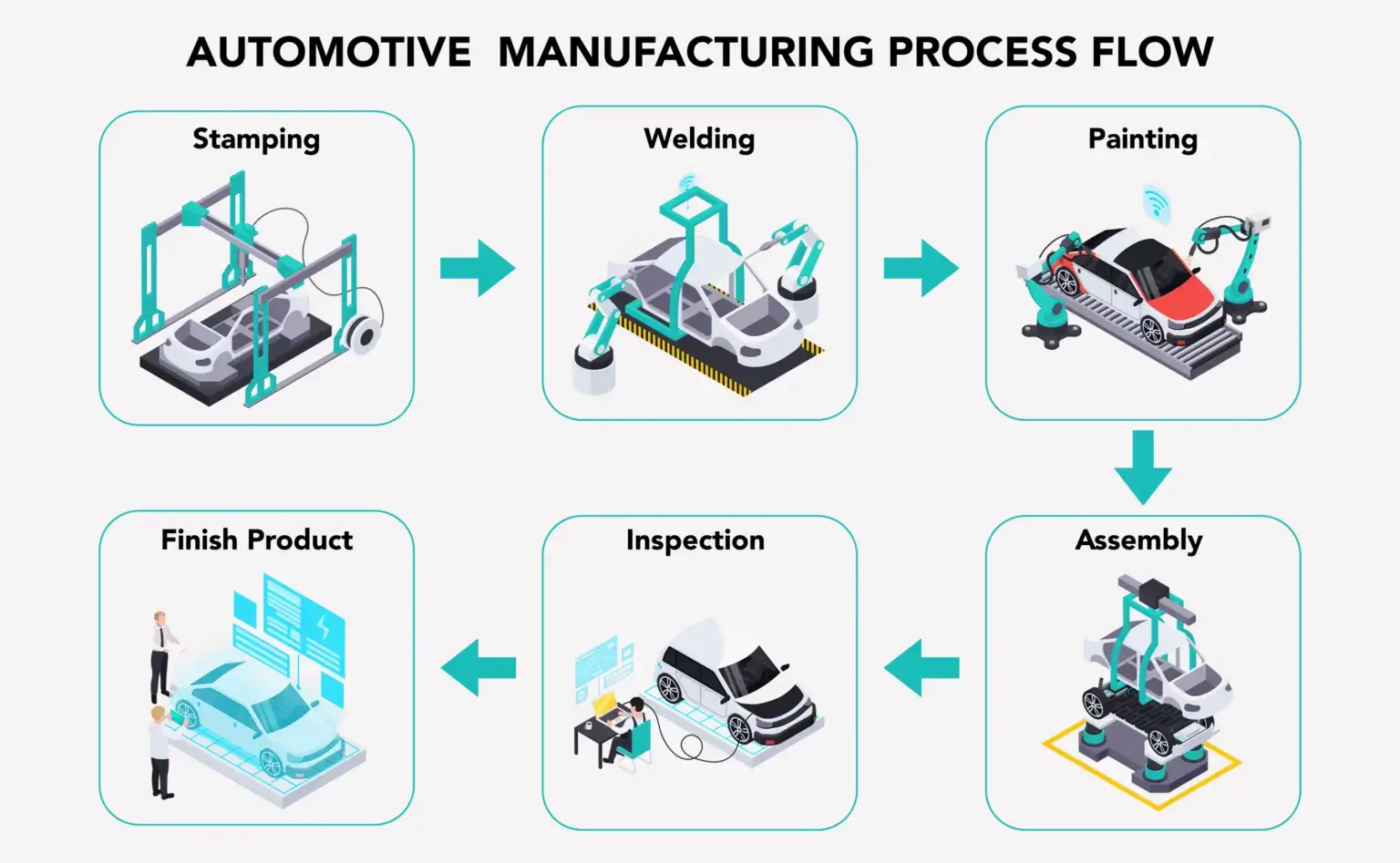

1. Automotive Manufacturing Processes & Where AMRs Fit In

Automotive manufacturing involves several stages, including:

-

Stamping - Forming metal sheets into components

-

Welding - Joining stamped parts into the vehicle frame

-

Painting - Surface treatment and protective coating

-

Assembly - Powertrain, chassis, electricals, and interior installation

-

Inspection - Quality control via machine vision and diagnostics

-

Logistics - Transporting the final product to distribution

Each of these stages benefits from automated transport solutions. AMRs from SK Robotics ensure that parts and assemblies are delivered just-in-time, without interrupting production flow.

2. Traditional Material Handling: Where It Falls Short

Traditional systems - conveyors, forklifts, manual carts, and tugger trains - have supported the industry for decades, but bring several limitations:

- Labor-intensive and costly

- Susceptible to human error and downtime

- Inflexible in dynamic manufacturing setups

- Inefficient inventory tracking and material delivery

- Energy consumption from legacy equipment

These challenges underscore the growing need for intelligent, adaptable solutions like AGVs and AMRs.

3. AGVs & AMRs: Solving Automotive Biggest Logistics Challenges

SK Robotics’ AMRs are engineered to tackle real-world automotive challenges:

- Autonomous Transport - Move raw materials, assemblies, and finished goods without manual handling.

-

Boosted Productivity - Automate repetitive tasks and reduce line interruptions.

-

Increased Flexibility in Manufacturing - With a Fleet Management System, multiple AGVs / AMRs can coordinate tasks and reroute in real-time, enabling smart workflows, seamless task switching, and effortless scalability in operations.

-

Data Integration - Sync with ERP and WMS for real-time inventory and delivery tracking.

-

Enhanced Safety in the Workplace - With built-in collision avoidance systems and real-time monitoring, AGVs / AMRs minimize workplace accidents and create a safer environment for employees

- Scalable Efficiency - Deploy the same AMR system across multiple facilities with minimal reconfiguration.

4. Benefits of AMRs in Automotive Manufacturing

-

High Production Volumes - AMRs keep pace with automotive output demands.

- ROI & Cost Savings - Reduce labor costs and errors, delivering strong return on investment.

-

Safety First - Improved working conditions with fewer manual interactions.

-

Cross-Facility Standardization - Easier rollout of proven solutions across global plants.

-

Data-Driven Optimization - Real-time analytics help improve efficiency and enable predictive maintenance.

5. The SK Robotics Edge

As the industry embraces smart automation, SK Robotics is delivering robust, adaptable AMR solutions designed for real-world factory environments. Whether it's transporting a chassis, delivering parts to the line, or feeding painting stations, our AMRs and custom units operate with:

- High payload capacity

- Advanced LiDAR navigation

- Fleet coordination and adaptive routing

- Easy integration with existing systems