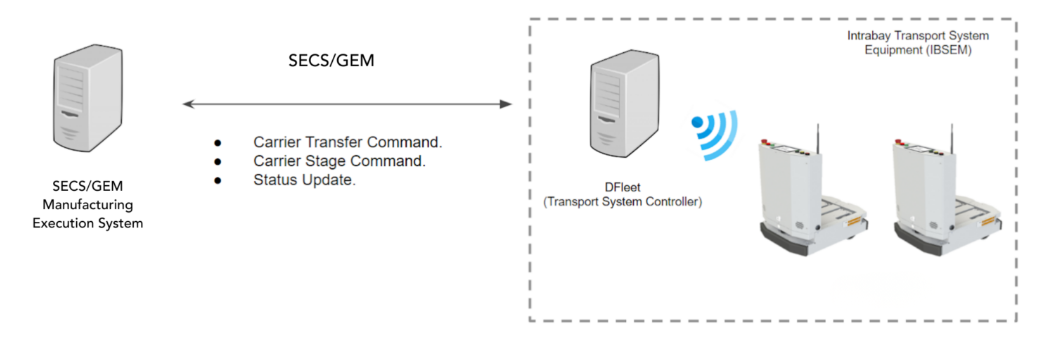

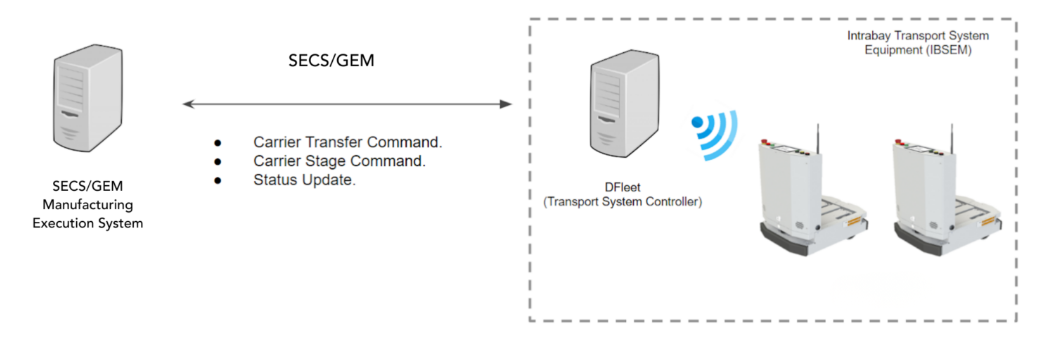

In semiconductor and electronics manufacturing, various machines handle different stages of production, from Printed Circuit Board (PCB) assembly and etching to soldering and final packaging. To streamline communication between these systems, the SECS/GEM protocol (SEMI Equipment Communication Standard / Generic Equipment Model) provides a unified communication standard.

This protocol allows a host system (the central controller or Manufacturing Execution System, MES) to integrate and manage multiple machines without requiring different communication methods. Through SECS/GEM, recipe changes and process updates can be made consistently and accurately. The host can also configure machines, monitor performance, and collect production data in real time. Additionally, any system alarms are sent directly to a centralized control system, enabling quick response and efficient oversight.

How DFleet and NavWiz Fit into the SECS/GEM Protocol

DFleet oversees and optimizes Autonomous Mobile Robots (AMRs) throughout the facility. It coordinates task assignments, manages fleet routes, balances battery usage, and handles charging schedules.

NavWiz, on the other hand, is the intelligent software platform behind SK Robotics’ AMRs and Automated Guided Vehicles (AGVs). It includes functions such as robot programming, live status monitoring, and intelligent navigation. Together, DFleet and NavWiz form a connected ecosystem that ensures seamless coordination between mobile robots and production lines.

Supported SEMI Specification

EOS SEMI Equipment Communication Standard 2 SECS-II

E30 Generic model fur communication and control of manufacturing quipment (GEM)

E82 Interbay/ltrabay Automated Material Handling System IRSEMI

SEMI Standards Supported by DFleet

DFleet supports SEMI E05, E30, and E82 standards. The E82 standard, in particular, enables the host system to issue transfer commands — extending beyond simple communication with production machines to managing material movement across the facility.

For example, the host can control transfers from warehouse stockers to production tools or between process stages, all through DFleet. The system continuously reports fleet and safety statuses, eliminating the need for the host to communicate with each AMR individually. Real-time updates are sent whenever an AMR changes state, ensuring full visibility into operations.

DFleet Implementation of SEMI Specifications

By implementing SEMI standards, DFleet allows the host to define key transfer details such as item IDs, source and destination points, and delivery timelines. The host can also issue standby, cancel, or abort commands when necessary.

Event reporting keeps the host updated on transfer progress, AMR status, and queue changes, ensuring transparency and control throughout the process. Real-time carrier tracking and immediate alerts for AMR alarms enable quick troubleshooting and operational resilience.

The system also supports comprehensive data collection, allowing the host to check AMR status, monitor active transfers, and review transfer histories.

NavWiz complements this by using SECS/GEM E84, which governs safe machine-to-AMR communication, ensuring proper handshakes during material transfers.

Applications for Intralogistics Automation

Here’s a real-world example: The host system monitors production equipment and detects when additional materials are needed. It sends a command to a stocker to prepare those materials while simultaneously notifying DFleet to dispatch an AMR to the stocker’s port.

Once materials are ready, the AMR confirms the carrier ID, picks up the load, and delivers it to the designated machine. Throughout the process, DFleet provides live status updates to the host system, ensuring full visibility from start to finish. After delivery, both the AMR and production system automatically update the host.

Conclusion

By integrating with SECS/GEM standards, DFleet and NavWiz enable a new level of intralogistics automation within semiconductor and electronics manufacturing. Through standardized communication, automated task coordination, and real-time visibility, DFleet transforms material handling from a manual process into an intelligent, integrated operation, bridging the gap between robotics and advanced manufacturing systems.